Choosing the Perfect Robot Integrator

How do manufacturers pick the perfect robot integrator to build their assembly machinery or their next robotic automation system? When I ran the marketing department for large automation integrator, I was thinking about this all the time. It was important for me always to be thinking of the big picture and asking the bigger questions. This is a complex question because of the apples to oranges problem, but can still be addressed through some basic analysis. One of the more effective methods is to judge vendors in rank order, assigning a weighting to key factors of your project, industry or company. Once you have weighted and ranked, the decision or at least the cut-off is a lot simpler and will seem clearer.

Get to know your automation integrator. Knowing exactly who you want to do business with is a key thing to identify as a manufacturer. Building sophisticated machinery is indeed a complex task and knowing the people with whom you‘re placing your trust and investment dollars is worth the time of research and face-to-face meetings. Asking for references, team member resumes and project successes are all reasonable requests, and should be willingly provided. Getting to know the President and senior management team, the application engineers and the project team that can, may or will build, program and commission your automation system will give you utmost confidence in your decision.

Technical capabilities matter. Experience within your specific industry and niche should really be a bar of entry. Certifications such as and including ISO, FDA, EU, GMP Compliance, nuclear, medical device or welding, specific to your automation needs, are basic technical standards; don’t even consider partnering with a company who won’t happily provide documentation of their certifications and industry experience.

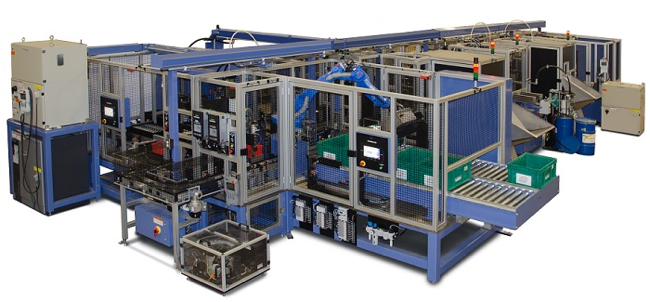

Quality should be evident. Quality in the automation build industry tends to show itself everywhere. You can see attention to detail in quotation documents, an engineering study, a facility tour, an electrical cabinet and machinery on the floor or a visit to a manufacturer where the integrator has previously installed their machinery.

Open the books. Understanding your supplier’s financial position is critical. Only doing business with a company that is profitable just makes basic sense. It demonstrates management maturity and company sustainability. Can they support a big project as well as small projects? A long-term project with extended build time, multiple lines or extended installation? Talk to their supply chain and past and non-competing customers.

Do a corporate culture temperature check. What kind of company is the potential integrator? Do they invest in their employees? How much do they spend in training? How many engineers do they have on staff? What is the average length of an employee stay at the company? Do they belong to an association like the Robotics Industry Association or support schools, STEM and education? These are all important questions that may help to determine if your cultural values and those of a potential key supplier are in sync.

Do your needs match their ability to deliver? When considering a supplier, make sure that their capabilities, locations and scale, match your size and relative needs. Picking too large or too small an integrator will put you at the front of the line or at the back of the line when it comes to attention, flexibility or any rush support or service that your project may require.

Flexibility is important. Not every company has every talent and skill at the time when you need it, especially in the robot integration business. Find out how the machine builder plans to mitigate any risks and bring in talent or resources to support your project, when they may need additional mechanical designers or electricians during the build phase of the project.

Supply chain is a key element to project success. Today more than ever, when you are building custom complex machinery, a good rapport with suppliers is simply not enough. Integrators need excellent cooperation with their supply chain. Equipment delivery, warranties, training, replacement parts, pricing and discounts are all things that have a price and your integrator must have great relationships with the industry supply chain to ensure the best value for their end customer.

Look at company reputation. When doing your research and due diligence, consider visiting one or more non-competing installations of your prospective machine builder. Interview purchasing, the project manager, the maintenance team and don’t forget to talk to the machine operators. All will have a slightly different perspective. Keep in mind that you should visit machines that have been installed and are working well for at least six months.

Is innovation crucial? Innovation is indeed highly important in the automation industry, but manufacturers may not always need an innovative solution. Maybe you need a flexible solution for your products. Understanding your needs for this particular automation program or machinery can make the difference in many areas of your solution, from price and delivery, to service and support.

Price is important, but not the only consideration. Payback, total cost of ownership (TCO) and return on investment are the critical financial elements, but initial price may not be. Today, most automation requires a 24 month or less performance in financial return. Getting automation delivered on time, commissioned quickly, and ramped to full production can take months off the purchase price and can make a gap in the price between two competitors a much smaller difference than may seem initially evident.

Industry 4.0 Readiness. The world in manufacturing is changing and choosing an integrator that knows how to handle information from many sources including robots, machine vision, external databases, archives and integration to many other data sources for tracking and tracing is becoming more important as manufacturers invest in data to make their facilities more competitive.

Here are some tips on how to effectively work with automation integrators and machine builders to lower risk, price, engineering time and get automation delivered faster:

* Partner early with your chosen automation integrator

* Get the legal agreements cemented quickly. These agreements can be very complex and can add weeks and months to a project schedule, especially when you start considering the implications of intellectual property ownership and sharing of patents.

* Reduce technical risks by engaging a prospective integrator in an engineering study on any complex discrete high risk area in your project such as machine vision, tooling or precision dispense.

If you like this article, consider sharing it to your network and join our newsletter at www.customerattraction.com/join

Categories

Recent Posts

- Trade Show Rule #1 Always Speak at Trade Shows 03th Jul 2023

- Are You Buying Email Lists? 06th Apr 2023

- Who are the Robot Manufacturers in Canada? 11th Mar 2023